Welding Rods Guide: Explained A Simple Guide for Beginners and Professionals

Choosing the right welding rod (also called a stick electrode) is crucial for creating strong, defect‑free welds. Stick welding remains popular because the rods combine filler metal with flux; the flux coating shields the molten weld pool from the atmosphere and introduces de‑oxidisers and alloying elements. According to a 2025 industry report, the global market for welding electrodes was about US$3 billion in 2019 and is forecast to reach US$4.46 billion by 2032, a compound annual growth rate (CAGR) of 2.8 %. Asia‑Pacific accounted for roughly 33 % of the market in 2019, reflecting the region’s rapid industrialisation and infrastructure projects.

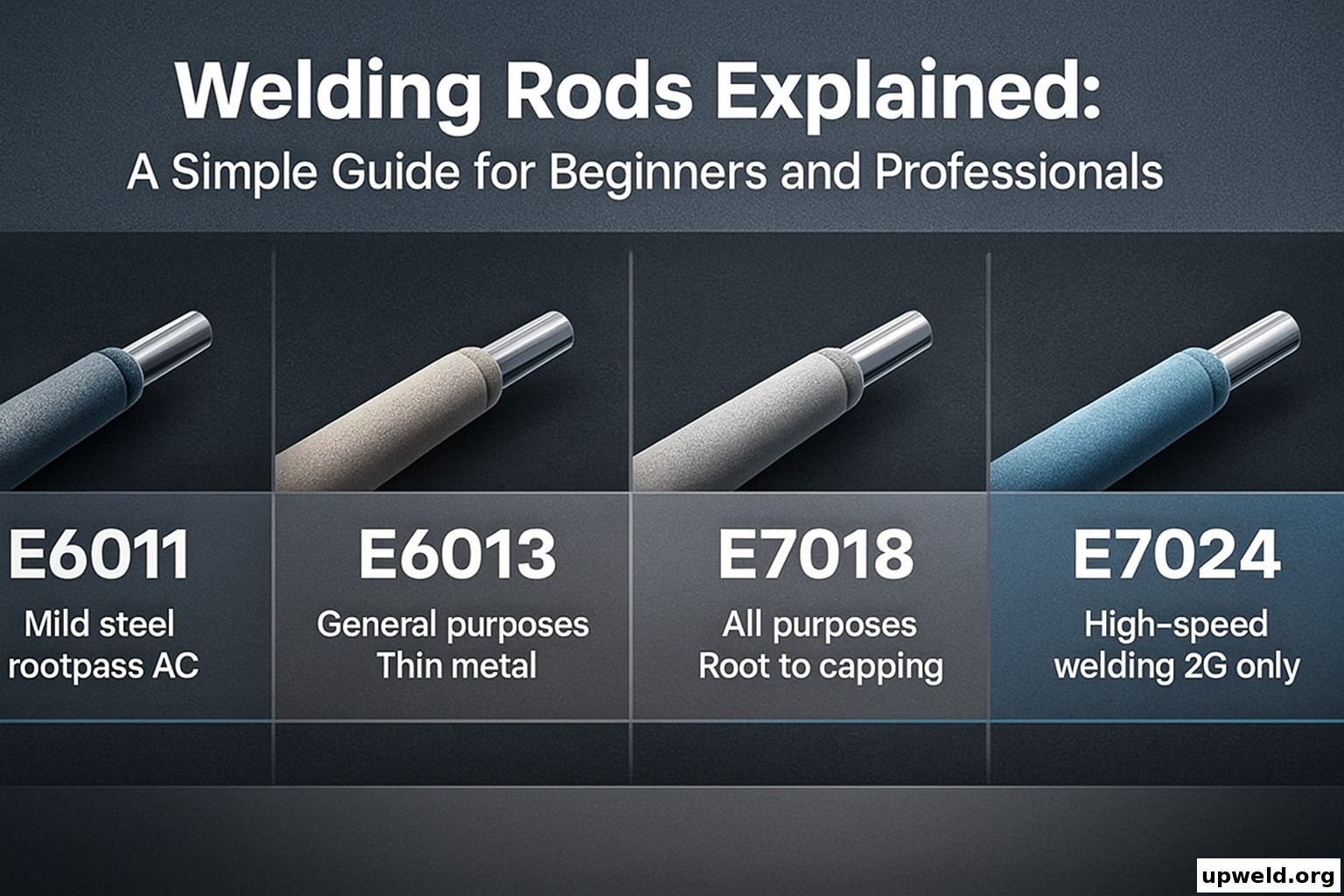

Many beginners get confused by the alphanumeric codes printed on welding rods. The code describes the rod’s tensile strength, welding position and flux/coating type. This guide breaks down the most common electrodes — E6011, E6013, E7018 and E7024 — and explains how to select the right rod for your project.

Understanding the electrode code

A welding rod code has three or four parts:

-

“E” stands for electrode – it indicates a stick rod used for shielded metal arc welding.

-

First two digits: minimum tensile strength of the deposited weld metal in thousands of pounds per square inch (ksi). For example, E6011 has a minimum tensile strength of 60 ksi (≈413 MPa) while E7018 has a minimum strength of 70 ksi (≈483 MPa).

-

Third digit: welding position the rod is designed for. A “1” means the rod can be used in all positions (flat, vertical, horizontal and overhead); “2” limits it to flat and horizontal.

-

Last digit(s): describe the coating type and current. For example, “1” on E6011 denotes a high‑cellulose potassium coating suitable for AC or DC+, whereas “18” on E7018 identifies a low‑hydrogen potassium/iron‑powder coating usable on AC, DC+ or DC–.

Understanding these numbers helps welders quickly identify a rod’s strengths and limitations.

Comparing common mild‑steel electrodes

The table below summarises key properties of four popular stick electrodes. (Tables are kept concise for clarity; full explanations follow in the text.)

| Electrode | Tensile strength & yield strength* | Position / current | Typical uses & notes |

|---|---|---|---|

| E6011 | Tensile ≈73,500 psi; yield ≈60,000 psi; elongation 24 % | All positions; AC | Excellent penetration and works on rusted/painted metal. Popular for maintenance and farm equipment |

| E6013 | Tensile ≈76,500 psi; yield ≈66,500 psi; elongation 25 % | All positions; AC | Smooth arc with shallow to moderate penetration. Forgiving for beginners and good for clean sheet metal |

| E7018 | Tensile ≈82,670 psi; yield ≈69,610 psi; elongation 30 % | All positions; AC, DC+, DC– | Low‑hydrogen rod with medium penetration and minimal spatter; favoured for structural welding and high‑strength applications |

| E7024 | Tensile ≈70,000 psi; yield ≈58,000 psi; elongation 17 % | Flat & horizontal; AC, DC+ | High‑deposition rod with thick flux; excellent for fast fillet welds on thick plate |

*Tensile and yield strengths are based on typical as‑welded test results and may vary slightly by manufacturer.

E6011 – versatile repair rod

Strength & composition – E6011 rods produce a weld with typical tensile strength around 73,500 psi and yield strength of 60,000 psi with 24 % elongation. The high‑cellulose potassium coating allows for deep penetration, making them ideal for welding through rust, paint or light contamination. The rods can be run on AC power, making them compatible with basic transformer welders.

Typical uses – E6011 is widely used for maintenance and repair, farm equipment and pipeline work. The robust arc strikes easily, penetrates deeply and fills gaps. However, controlling the arc requires experience and may be challenging for beginners.

E6013 – general‑purpose electrode

Strength & composition – E6013 rods deliver a tensile strength of about 76,500 psi and yield strength around 66,500 psi with 25 % elongation. They use a high‑titania potassium coating that stabilises the arc and produces a smooth bead.

Characteristics – The arc is softer than E6011 and produces low spatter with shallow to moderate penetration. This makes E6013 suitable for clean sheet metal, thin materials and projects where a neat appearance is important. Because the flux contains iron powder, the slag freezes quickly and is easy to remove. These rods are very forgiving and are often recommended to new stick‑welders.

E7018 – low‑hydrogen, high‑strength rod

Strength & composition – E7018 is a low‑hydrogen electrode designed for welding structural steels. The deposited weld metal typically has a tensile strength of around 82,670 psi, a yield strength of 69,610 psi and 30 % elongation. Because the flux contains iron powder and moisture‑absorbing compounds, the rods must be stored in a dry oven to prevent hydrogen pick‑up.

Benefits – E7018 produces smooth, high‑quality welds with medium penetration and minimal spatter. It can be used on AC, DC+ or DC– in all positions. The combination of strength and ductility makes it suitable for structural welding, pressure vessels, bridges and shipbuilding. The higher cost and need for careful storage are trade‑offs.

E7024 – high‑deposition rod for flat welds

Strength & composition – E7024 rods are designed for fast, flat or horizontal fillet welds. They deliver tensile strength of roughly 70,000 psi, yield strength of 58,000 psi and 17 % elongation. The coating includes rutile titania oxide and a high proportion of iron powder, which greatly increases deposition rates.

Characteristics – These rods produce a large weld pool with a slightly convex bead and self‑releasing slag. They are excellent for quickly welding thick, clean steel plate in the flat or horizontal position but are unsuitable for vertical or overhead welding. Recommended amperage ranges from 70 A for 3/32 in. rods to 390 A for 3/16 in. rods.

Selecting a welding rod

When choosing a welding rod, consider:

-

Base metal and strength requirements – Use the first two digits to match the tensile strength of the rod to the base metal. For example, E7018’s 70 ksi strength suits high‑strength steels, whereas E6013’s 60 ksi is adequate for mild steel sheets.

-

Welding position & joint type – E6011 and E6013 can be used in all positions, while E7024 is limited to flat and horizontal work.

-

Arc characteristics & penetration – For deep penetration through rust or paint, choose E6011. For a smooth bead on clean metal, use E6013. For structural, low‑hydrogen welds with high strength, opt for E7018. For fast fillet welds on heavy plate, select E7024.

-

Power source – Ensure your welder provides the required current (AC, DC+ or DC–) indicated by the last digit. For example, E6011 works on AC only, whereas E7018 is versatile and runs on AC or DC.

-

Skill level – Beginners often prefer E6013 because of its forgiving arc and clean appearance. E6011 requires more control but excels in repair work.

Industry context and future trends

The welding electrode market is expected to expand steadily as infrastructure and manufacturing projects multiply. A 2025 report projected that the global welding electrodes market would grow from US$3 billion in 2019 to US$4.46 billion by 2032, with Asia‑Pacific holding about 33 % of the market share. Demand is driven by building & construction, oil & gas, automotive and shipbuilding sectors. Meanwhile, innovations such as low‑hydrogen electrodes and iron‑powder flux coatings improve deposition rates and weld quality, catering to automated and precision welding processes.

Conclusion

Understanding the electrode numbering system and the properties of common welding rods empowers both beginners and professionals to make informed choices. Stick electrodes like E6011, E6013, E7018 and E7024 each serve distinct purposes — from deep‑penetration repair work to high‑strength structural welds and high‑speed fillet welds. By matching the rod’s tensile strength, position rating and coating to the job requirements, welders can achieve safe, reliable and aesthetically pleasing welds.

“E” stands for electrode, meaning it conducts current to form the weld.

E6011 penetrates deeper and works on dirty metals, while E6013 provides cleaner, smoother welds.

Yes, but they perform best with DC+ for deeper penetration.

E6013 — it’s easy to control and creates neat welds with minimal spatter.

Keep them in a rod oven at 250°F to prevent moisture absorption.

No — use stainless-specific rods like E308L or E309L instead.