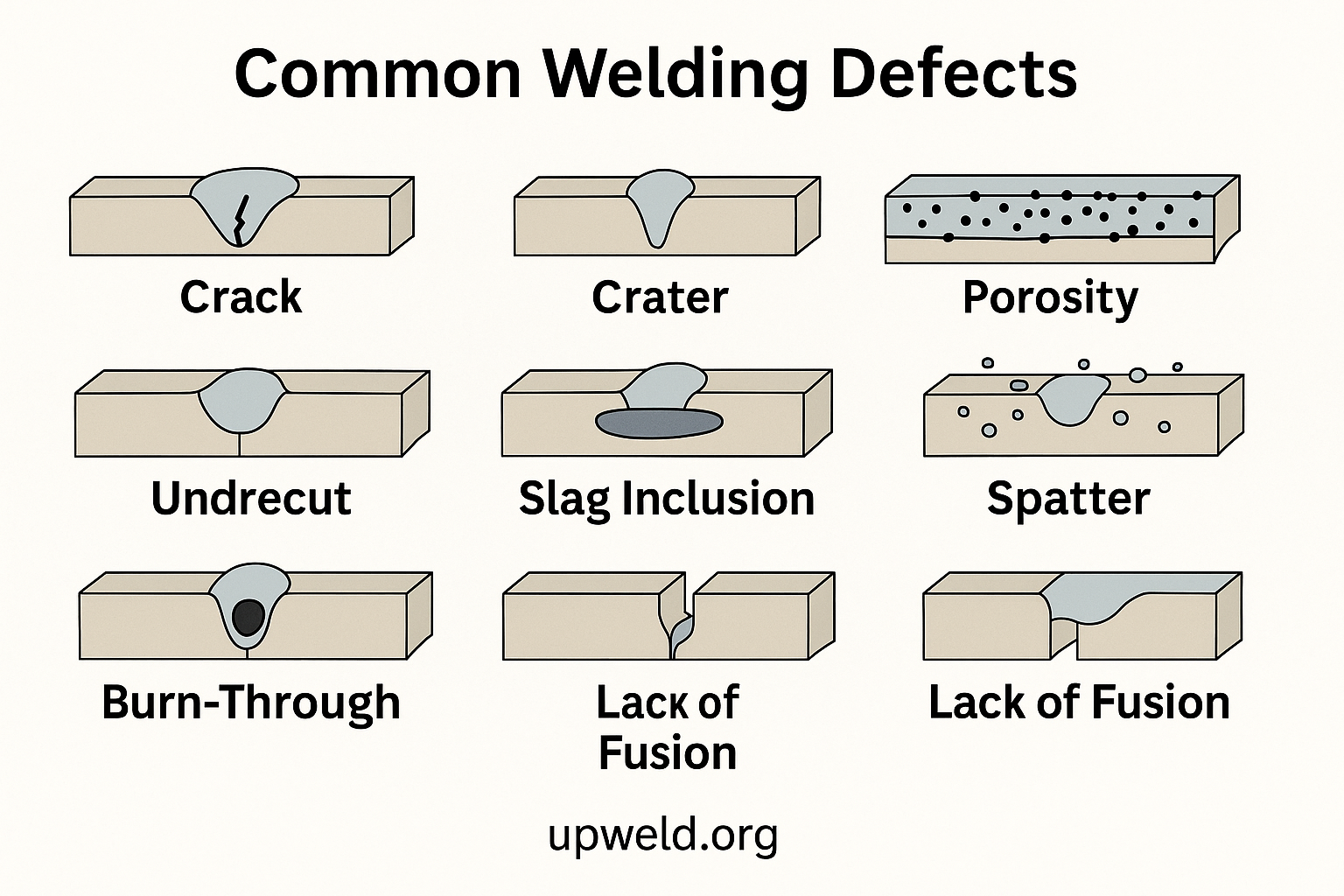

Common Welding Defects Every Welder Must Know

Common Welding Defects Every Welder Must Know (With Clear Explanations & AWS/ISO References) Welding defects reduce joint integrity, increase repair costs, and can lead to catastrophic structural failures if left unchecked. According to the American Welding Society (AWS), more than 65% of weld failures in field inspections can be traced back to preventable weld discontinuities—not … Read more