Common Welding Defects Every Welder Must Know (With Clear Explanations & AWS/ISO References)

Welding defects reduce joint integrity, increase repair costs, and can lead to catastrophic structural failures if left unchecked. According to the American Welding Society (AWS), more than 65% of weld failures in field inspections can be traced back to preventable weld discontinuities—not design errors.

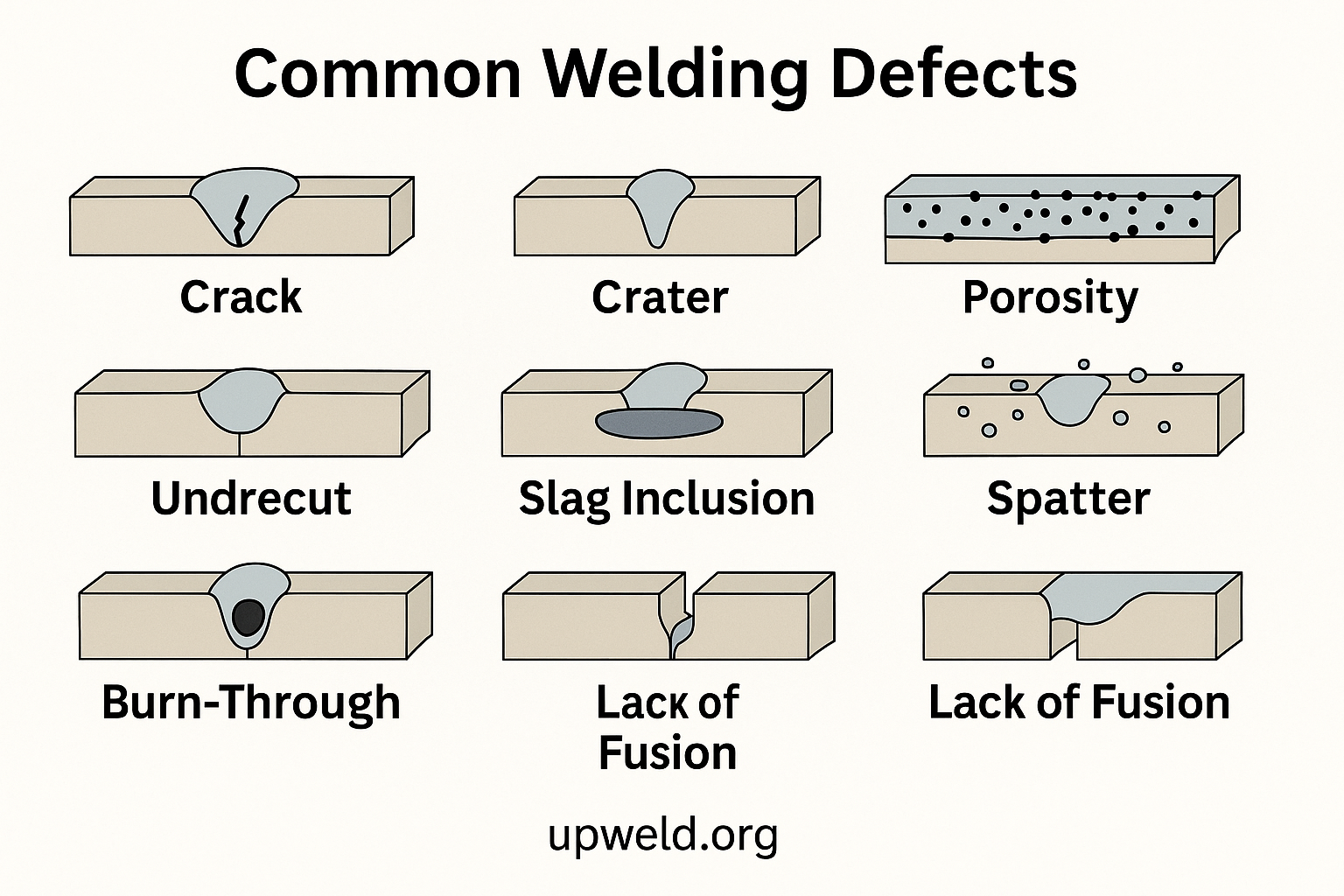

This detailed guide explains the most common welding defects, their causes, effects, visual indicators, and relevant code references from AWS A3.0, AWS D1.1, and ISO 6520-1. Whether you’re a welder, inspector, or trainee, this article gives you everything you need to identify and understand these defects with clarity and confidence.

Why Welding Defects Matter

Welding discontinuities affect:

-

Structural safety

-

Mechanical performance

-

Corrosion resistance

-

Fatigue life

-

Cost, time, and project delivery

Studies from AWS D1.1 show that welds with porosity, cracks, or lack of fusion have up to 40–60% lower strength compared to sound welds. Identifying defects early prevents failures and improves overall weld quality.

1. Crack (AWS Discontinuity Type: 1000 Series)

A crack is a fracture-type defect that indicates severe weakness. It can appear in the weld metal, heat-affected zone (HAZ), or base metal.

Causes:

-

High cooling rate

-

Excessive residual stress

-

Improper preheat or interpass temperature

-

High restraint during welding

-

Poor joint design

Effects:

-

Considered a critical defect — never acceptable

-

Leads to immediate or progressive cracking

-

Can propagate under stress, vibration, or thermal load

Standard References:

-

AWS A3.0 – Crack definition

-

AWS D1.1 – Always unacceptable

-

ISO 6520-1: Code 1000

2. Crater

A crater appears as a small “dip” or depression at the end of the weld, often seen when the welder breaks the arc too quickly.

Causes:

-

Stopping the electrode abruptly

-

Not filling the crater before extinguishing the arc

Effects:

-

Often leads to crater cracks, especially in aluminium

-

Reduces fatigue life of the weld

Standard Notes:

-

Addressed under weld terminations in AWS D1.1 Clause 5

-

The crater must be adequately filled

3. Pinholes (Porosity – ISO 6520-1 Code 100)

Porosity consists of trapped gas cavities within the weld metal. “Pinholes” are the visible surface expressions of these gas pockets.

Causes:

-

Moisture or oil contamination

-

Improper shielding gas coverage

-

Dirty surface or rust

-

High welding speed

-

Low gas flow

Effects:

-

Reduced ductility and strength

-

Increased risk of crack initiation

-

Poor weld appearance

Standard References:

-

AWS A3.0 / AWS D1.1 Table 6.1

-

ISO 6520-1: Code 100 – Gas Porosity

4. Undercut (ISO 6520-1 Code 501)

Undercut is a groove melted at the weld toe that is not filled with weld metal.

Causes:

-

Excess welding current

-

Incorrect torch or electrode angle

-

Excess travel speed

-

Poor weaving technique

Effects:

-

Reduces effective throat thickness

-

Acts as a stress riser

-

Can lead to cracking and fatigue failure

Standards:

-

AWS A3.0

-

AWS D1.1 Clause 5 & Table 6.1 – Acceptability limits

-

ISO 6520-1: Code 501

5. Residual Slag (Slag Inclusion)

Slag trapped inside the weld metal or at the weld interface.

Causes:

-

Incomplete cleaning between passes

-

Incorrect travel angle

-

Low heat input

-

Poor electrode manipulation

Effects:

-

Leads to a lack of fusion

-

Weakens weld strength

-

Risk of crack propagation

Standards:

-

AWS D1.1 Table 6.1 – Slag Inclusion

-

ISO 6520-1: Code 200 Series

6. Weld Spatter

Small metal droplets are scattered around the weld area.

Causes:

-

Incorrect voltage or current

-

Poor wire feed settings

-

Contaminated workpiece

-

Long arc length

Effects:

-

Affects weld appearance

-

Increases time spent on grinding/cleaning

-

May interfere with coatings

Referenced In:

-

General spatter guidance in AWS welding handbooks

-

ISO 6520-1 may classify excessive spatter as surface irregularity

Additional Critical Defects Every Inspector Must Know

Below are additional major defects frequently referenced in both structural and pressure-code inspections.

7. Burn-Through (ISO 6520-1 Code 401)

Molten weld metal burns completely through the base metal.

Causes:

-

Excess heat

-

Thin base metal

-

Slow travel speed

Reference:

-

AWS A3.0 – Burn-Through definition

-

ISO 6520-1: Code 401

8. Lack of Fusion (ISO 6520-1 Code 4012)

Weld metal does not properly fuse with the base metal or previous weld pass.

Causes:

-

Low heat input

-

Incorrect electrode manipulation

-

Insufficient cleaning

-

High travel speed

Why It’s Serious:

-

Creates weak, unfused interfaces

-

Hidden defect detected via UT or RT

References:

-

AWS D1.1 Table 6.1

-

ISO 6520-1 Code 4012

Comparison Table: Common Welding Defects & Code References

| Defect | AWS Standard | ISO Standard | Severity |

|---|---|---|---|

| Crack | AWS A3.0 / D1.1 | ISO 1000 | Critical |

| Crater Crack | AWS D1.1 | ISO 131 | High |

| Porosity | AWS A3.0 / D1.1 | ISO 100 | Medium |

| Undercut | AWS D1.1 Table 6.1 | ISO 501 | Medium–High |

| Slag Inclusion | AWS D1.1 | ISO 200 Series | High |

| Burn-Through | AWS A3.0 | ISO 401 | Medium |

| Lack of Fusion | AWS D1.1 | ISO 4012 | Critical |

| Spatter | AWS recommendations | ISO surface irregularity | Low |

Preventive Tips to Avoid Welding Defects:

- Proper Cleaning: Remove rust, oil, moisture, and paint.

- Control Heat Input: Follow WPS (Welding Procedure Specification) limits.

- Maintain Correct Parameters: Adjust current, voltage, wire feed, and travel speed.

- Follow Preheat & Interpass Requirements: Reduces cracking and porosity.

- Use Correct Technique: Maintain proper angle, arc length, and steady travel.

- Conduct NDT: Use VT, UT, RT, MT, PT as required.

Conclusion

Welding defects are unavoidable in fabrication, but with the right knowledge, they are completely manageable. By understanding how each defect forms, what it looks like, and how AWS & ISO define it, welders and inspectors can significantly improve weld quality and reduce rework.

Proper inspection, parameter control, cleanliness, and adherence to WPS are the keys to producing consistent, high-quality welds.

The most common welding defects are cracks, porosity, undercut, lack of fusion, burn-through, slag inclusion, spatter, and crater cracks. These discontinuities reduce weld strength and quality and are referenced under AWS A3.0, AWS D1.1, and ISO 6520-1.

Porosity is caused by moisture, contamination, poor shielding gas coverage, excessive travel speed, or dirty base materials. ISO 6520-1 classifies porosity under Code 100.

Lack of fusion happens when the weld metal fails to fuse with the base metal or previous pass. Causes include low heat input, incorrect travel speed, or poor joint cleaning. AWS D1.1 categorizes it as a critical defect.

Prevent undercut by maintaining correct travel speed, using proper voltage/current settings, and keeping the electrode angle appropriate. Undercut falls under ISO 6520-1 Code 501.

Burn-through occurs when excessive heat melts a hole through the base metal. It is common in thin materials. ISO 6520-1 lists burn-through under Code 401.

Cracks occur due to high cooling rates, residual stress, poor preheat, wrong filler metal, or excessive restraint. AWS D1.1 states cracks are never acceptable, regardless of size.

Slag inclusion is trapped slag that forms between weld layers or between the weld metal and base metal. It is caused by poor cleaning between passes or incorrect technique.

Weld spatter is not always structurally harmful but is considered a surface discontinuity. Excessive spatter increases cleanup time and affects the finish of the weld.

Inspectors use NDT methods—UT (Ultrasonic), RT (Radiography), MT (Magnetic Particle), PT (Dye Penetrant), and VT (Visual Testing)—as required by AWS D1.1 Clause 6 and ISO 17637.

Defects such as cracks, lack of fusion, and crater cracks are always unacceptable per AWS D1.1 Table 6.1. Other defects may be accepted depending on size and location.